Luggage Hinge Machine for High-Precision Suitcase Production

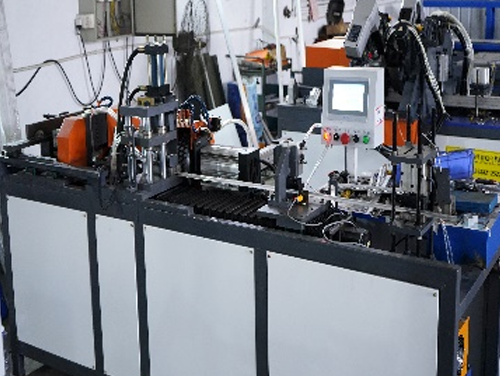

The Luggage Hinge Machine for High-Precision Suitcase Production is a state-of-the-art industrial solution designed for accurate hinge assembly in hard-shell and soft-shell luggage manufacturing. Precision and consistency are essential in luggage production to ensure durability, smooth opening and closing, and high-quality finish. This machine integrates CNC automation, high-speed cutting mechanisms, and adjustable settings to meet the demands of modern manufacturing lines.

Whether producing ABS, polycarbonate, or aluminum suitcases, this machine optimizes labor efficiency, reduces human error, and guarantees consistent performance. This article explores its specifications, core functions, technical parameters, and material compatibility for manufacturers seeking a reliable industrial solution.

The Luggage Hinge Machine comes in various models to accommodate different production scales and suitcase types.

| Model | Maximum Production Speed | Compatible Hinge Types | Power Requirement | Dimensions |

|---|---|---|---|---|

| LHM-200 | 50 pcs/min | Standard, TSA-approved | 3.0 kW | 1800x800x1500 mm |

| LHM-300 | 70 pcs/min | Standard, TSA-approved, Custom | 4.5 kW | 2000x900x1600 mm |

| LHM-400 | 100 pcs/min | All commercial hinges | 5.5 kW | 2200x1000x1700 mm |

Key Highlights of Each Model:

LHM-200: Ideal for small-scale factories or specialized luggage production.

LHM-300: Suitable for medium-volume industrial operations with flexibility for custom hinges.

LHM-400: High-speed production for large-scale suitcase manufacturers, compatible with all hinge types.

The Luggage Hinge Machine offers multiple features designed to enhance productivity, precision, and safety.

The CNC-controlled feeding system positions the suitcase panels accurately and guides the hinge slots with high precision. This ensures uniform alignment across all pieces.

The machine allows operators to set cutting depth according to material thickness, whether ABS, polycarbonate, or aluminum, preventing material damage and ensuring a flush hinge fit.

Designed to handle a range of suitcase materials, the machine adapts automatically to different hardness levels, preventing excessive wear on cutting blades.

Equipped with blade guards, emergency stop buttons, and overload protection systems, the machine ensures operator safety while maintaining production efficiency.

The machine supports continuous operation at high production rates, reducing cycle time per suitcase and maximizing throughput without compromising accuracy.

| Parameter | Specification |

|---|---|

| Power Supply | 380V/50Hz three-phase |

| Motor Power | 3.0–5.5 kW depending on model |

| Maximum Cutting Speed | 100 pcs/min |

| CNC Control Accuracy | ±0.05 mm |

| Blade Type | Carbide or high-speed steel (HSS) |

| Noise Level | ≤75 dB |

| Operating Temperature | 0–45°C |

| Humidity | ≤85% (non-condensing) |

| Air Pressure Requirement | 0.6 MPa for pneumatic feed system |

Additional Features:

Digital touch-screen interface for easy program selection.

Automatic hinge alignment verification system.

Compatible with TSA-approved and custom hinge designs.

Adjustable clamp pressure for delicate materials.

The Luggage Hinge Machine is engineered for multi-material operation:

ABS Plastic: Lightweight and widely used in hard-shell luggage; the machine provides precise slots without cracking or deforming.

Polycarbonate Panels: Offers superior impact resistance; adjustable cutting speed ensures clean hinge integration.

Aluminum Frames: High-precision milling maintains structural integrity and ensures smooth hinge operation.

Composite Materials: Handles layered materials commonly found in premium luggage lines with uniform slotting performance.

By accommodating these materials, the machine allows manufacturers to diversify product lines without investing in multiple specialized tools.

Position the machine on a flat and stable surface.

Connect to the appropriate power supply and compressed air system.

Secure the machine according to manufacturer guidelines.

Calibrate CNC controls using test panels before production.

Always wear protective equipment, including gloves and safety goggles.

Verify material thickness and hinge type before operation.

Do not override safety mechanisms.

Monitor blade condition regularly for wear or damage.

Routine maintenance ensures consistent performance and prolongs machine life.

| Task | Frequency | Procedure |

|---|---|---|

| Blade Inspection | Daily | Check for wear; sharpen or replace as needed |

| Lubrication | Weekly | Apply recommended oil to moving parts |

| Cleaning | Daily | Remove dust, plastic shavings, or debris |

| CNC Calibration | Monthly | Verify alignment and precision |

| Safety Mechanism Test | Weekly | Check emergency stop and blade guards |

| Motor Inspection | Monthly | Inspect motor temperature and vibration |

Following a structured maintenance schedule minimizes downtime and preserves production quality.

Precision: High accuracy reduces errors and ensures consistent hinge placement.

Efficiency: Automated operations reduce labor costs and production time.

Versatility: Compatible with multiple materials and hinge types.

Durability: Robust construction supports long-term industrial use.

Safety: Advanced safety mechanisms protect operators.

Manufacturers across the luggage industry have reported significant improvements in production quality and efficiency.

High Precision: Operators notice consistent hinge alignment across multiple batches.

Ease of Use: CNC interface and automated feeding reduce the need for extensive operator training.

Reliability: Machines withstand continuous production in high-volume factories.

Productivity: Production rates increased by 30–50% in case studies with LHM-300 and LHM-400 models.

Safety: Integrated emergency stops and blade guards ensure accident-free operations.

Sample Testimonial:

"Integrating the Luggage Hinge Machine into our production line improved both speed and accuracy. The CNC control ensures every hinge slot is perfect, reducing assembly errors and saving labor hours." – Travel Gear Manufacturer, Germany

The Luggage Hinge Machine for High-Precision Suitcase Production is an essential tool for modern luggage manufacturers. With CNC precision, multi-material compatibility, high-speed operation, and robust safety features, it optimizes production efficiency while maintaining high-quality standards. Regular maintenance and proper operation ensure long-term reliability. Manufacturers looking to improve hinge assembly accuracy, reduce labor costs, and enhance factory productivity will find this machine a valuable investment.

This website uses cookies to ensure you get the best experience on our website.

Comment

(0)