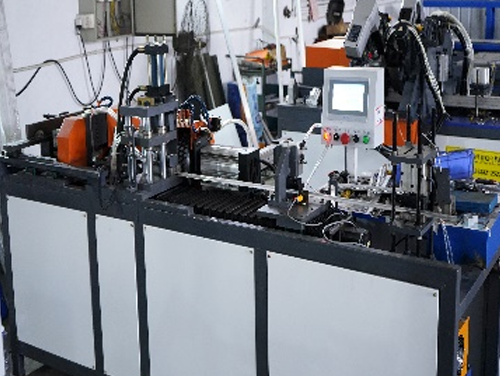

Automated luggage hinge fixing equipment: Complete Guide

The Automated Luggage Hinge Fixing Equipment is a high-precision industrial machine designed to streamline the assembly of hinges in luggage, travel bags, and other bag products. With advanced automation, intelligent positioning, and adjustable force controls, it ensures accurate and consistent hinge attachment while reducing manual labor. Widely used in luggage manufacturing plants and industrial assembly lines, this equipment enhances productivity, improves product quality, and minimizes errors. Its robust construction, user-friendly operation, and environmentally conscious design make it an essential tool for modern luggage production facilities seeking efficiency and sustainability.

Automated Hinge Positioning:

Precisely aligns hinges with suitcase frames for consistent attachment.

Adjustable Clamping Force:

Ensures secure hinge fixation without damaging the luggage material.

High-Speed Operation:

Supports large-scale production with rapid cycle times.

User-Friendly Interface:

Touchscreen control and programmable settings simplify operation and reduce training time.

Durable Construction:

Heavy-duty frame and industrial-grade components ensure long-term reliability.

| Parameter | Specification |

|---|---|

| Machine Type | Automated hinge fixing equipment |

| Hinge Compatibility | Standard suitcase, bag, and custom hinges |

| Production Speed | Up to 200 hinges/hour (depending on hinge type) |

| Power Supply | 380V / 50Hz |

| Control System | PLC or CNC interface with touchscreen |

| Operating Temperature | 10°C – 40°C |

| Dimensions | 1800 × 1200 × 1500 mm |

| Weight | 850 kg |

| Material Compatibility | ABS, aluminum, PU, leather, and composite panels |

The equipment addresses key challenges in luggage production, such as inconsistent hinge alignment, slow manual assembly, and quality control issues.

| Problem | Solution Provided by Automated Hinge Equipment |

|---|---|

| Manual hinge attachment errors | Automated alignment ensures consistent hinge placement |

| High labor costs | Reduces manual operation, lowering workforce needs |

| Slow production | High-speed operation increases throughput and efficiency |

| Material damage during assembly | Adjustable clamping force prevents dents or scratches |

| Quality inconsistencies | Digital monitoring ensures uniform hinge installation |

By implementing this machine, manufacturers achieve streamlined production, reduced error rates, and higher overall product quality.

For safe and efficient operation, follow these precautions:

Operator Safety:

Wear protective gloves and eyewear during operation.

Keep hands clear of moving parts.

Pre-Operation Checks:

Inspect hinge clamps, alignment sensors, and power connections before starting.

Ensure the control system is calibrated to the correct hinge type and size.

Material Handling:

Verify luggage panels are free of debris and properly positioned.

Avoid overloading the machine beyond its rated capacity.

Emergency Procedures:

Know the location of the emergency stop button.

Immediately power down the machine if abnormal noises or vibrations occur.

Routine Inspection:

Check the condition of pneumatic or hydraulic components regularly.

Ensure screws, bolts, and moving parts are tightened and lubricated.

Modern manufacturing increasingly requires environmentally responsible equipment. The Automated Luggage Hinge Fixing Equipment incorporates several eco-friendly features:

| Feature | Environmental Benefit |

|---|---|

| Low Power Consumption | Reduces electricity usage compared to older manual machines |

| Minimal Waste Design | Precise hinge placement reduces defective products |

| Noise Reduction | Optimized motor and hydraulic systems lower operational noise |

| Durable Components | Extended machine lifespan reduces the frequency of replacement and material waste |

| Recyclable Materials | Key machine parts are made from recyclable metals and plastics |

These features allow manufacturers to maintain high productivity while reducing their environmental footprint.

Proper maintenance ensures consistent performance and long service life:

| Maintenance Task | Frequency | Description |

|---|---|---|

| Cleaning | Daily | Remove dust, hinge residue, and debris from the work area |

| Lubrication | Weekly | Apply lubricants to linear guides, bearings, and moving components |

| Control System Check | Monthly | Verify calibration, update software, and test sensors |

| Pneumatic/Hydraulic System | Monthly | Inspect hoses, valves, and cylinders for leaks or wear |

| Blade & Clamping Parts | Monthly | Check for wear or deformation; replace as needed |

Tips:

Always disconnect power before performing maintenance.

Keep a maintenance log to track inspections, replacements, and repairs.

Use OEM replacement parts for consistent performance and warranty compliance.

Efficiency: Speeds up the hinge installation process, increasing overall production output.

Accuracy: CNC and sensor-controlled alignment ensures precise and consistent hinge placement.

Durability: Industrial-grade components guarantee long-term reliability under high-volume production.

Ease of Use: Programmable settings reduce operator training time and simplify operation.

Environmentally Friendly: Low power consumption, minimal waste, and recyclable materials support sustainable manufacturing practices.

The Automated Luggage Hinge Fixing Equipment is an indispensable tool for modern luggage manufacturing. By combining high-speed automation, precise hinge alignment, and environmentally conscious design, it addresses key production challenges while improving efficiency and product quality. Its robust construction, user-friendly interface, and low-maintenance requirements make it ideal for both small-scale workshops and large industrial assembly lines. Investing in this equipment ensures consistent hinge installation, higher throughput, and a reduced environmental footprint, providing manufacturers with a competitive advantage in the modern luggage market.

This website uses cookies to ensure you get the best experience on our website.